Green Global Projects

Environmentally Friendly Products and Services

Bio-based Urethane Foam: Our patented Bio-based foams are produced from plant based renewable resources. The products are water blown, formaldehyde free, contains no ozone depleting CFSs or HCFCs. The product has no food value and is water and moisture resistant.

Non-toxic, non-hazardous and Eco-friendly - unlike other foams, our is made with MDI instead of TDI (one of eleven hazardous substances that must be reported to the EPA when used). That makes Green Foam easier to use, safe (without even a noxious odor), and absolutely free from TDI' need for a metallic catalyst, like tin. Green Foam eliminates the danger of leeching banned metals into the environment

A unique chemical reaction gives Green Foam more cross link density, giving our products more elastic strength, and longer life! It also means our foam products are re-usable, saving you even more money.

Reusable foam pads, sponges, mops, and socks, make your job easier and safer

OIL SPILLS

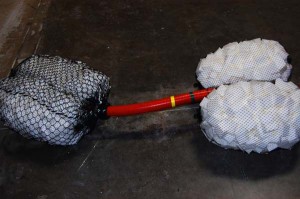

We have created a simple, cost-effective method to recover crude oil from bodies of water after a spill occurs. This is a re-usable, portable system of foam buoys that can keep an accidental oil spill from becoming so large that it becomes an environmental hazard. It's called the OIL EXTRACTOR SEA SPONGE.

OUR Foam Pads absorb and retain oil better than any other pad, allowing users to reclaim and reuse absorbed materials

Components are being assembled into oil spill clean up kits ranging from five gallons in capacity to units that will absorb a spill of 55 gallons.

FOR CONSTRUCTION AND INSULATION

Elastomeric Foams are a highly durable expanding foam material, which delivers a robust balance of toughness and flexibility. Its elastic toughness is used in demanding environments, specialty products and surface skinning applications within military, aerospace, industrial and commercial.

Rigid Foams offer a unique blend of properties, which yield excellent mechanical and thermally efficient structures. These foams deliver high compressive/shear strength, insulating capacity, overall toughness and impact resistance. Their high performance strength to weight ratio densities produce a wide range of applications for very diverse industries. As an energy saving material yielding very high insulating values, paralleled with its sound absorbing capability it has seen much use in the architectural and construction industries. Pour casting diversifies its uses to the areas of consumer product manufacturing, mold making, fine surface finish applications. These may be subsequently color top-coated, textured and clear coated to handle extensive outdoor rugged environments. These materials maintain dimensional stability and will not deform or distort within operating temperature of -100F to 250F. Fire retardant formulations are used in structural public buildings and warehouses. Installation cure times range from 30 sec.-30 min Physical Properties.

Uses for Soy-based foam:

Soy-based foam insulation is the environmentally friendly alternative to polyurethane made with petroleum and petroleum derivatives.

Properties of the Soy-based foam insulation:

| Tear Strength | ASTM D624 | 550 lbs/linear in. |

|---|---|---|

| Impact | ASTM D2794 | >300 in. lbs |

| Tensile Strength | ASTM D412 | 3610 psi |

| Elongation | ASTM D412 | >500% |

| Hardness -Shore A | ASTM D2240 | 92 |

| Abrasion -TaberCS18 | ASTM D4060 | 25 mg/1k cycles |

| Flash Point | ATSM Pensky | >200 F |

| ELASTOMERICS PHYSICAL PROPERTIES | ||

| Standard Densities: 15-25-36 lbs/ft3 | ||

| Flashpoint | ASTM P/M | > 200 °F |

| Flexibility | ASTM D1737 | 1/8″ All Pass |

| Tensile Strength | ASTM D412 | *< 3995 psi |

| Hardness | ASTM D785 | *Shore: 75A-45D |

| Abrasion -TaberCS18 | ASTM D4060 | *<110 mg/1k cycles |

| Chemical Resistance | List Available | |

| Water Absorption | ASTM D2842-01 | < 1 % |

| Tear Strength | ASTM D2240 | *>110 lbs/ lin. in. |

| Elongation | ASTM D412 | *<400% |

| * Values Relative to Foam Density | ||

| RIGIDS PHYSICAL PROPERTIES | ||

| Standard Densities: 0.5-20 lbs/ft3 | ||

| Flashpoint | ASTM P/M | > 200 °F |

| Closed Cell Content | ASTM D2842 | *50-90 % |

| Compressive Strength | ASTM D1621 | *10-3000 psi |

| Thermal Resistance | ASTM C518 | *4.0-6.5 |

| Water Vapor Transmission | ASTM E96 | *0.1-2.0 perms |

| Fungi Resistance | ASTM C1338 | Pass/ No growth |

| Water Absorption | ASTM D2842-01 | < 1 % |

| Tear Strength | ASTM D2240 | *>110 lbs/lin.in. |

| Flame Spread Index | ASTM E84 | <25 % |

| Smoke Index | ASTM E84 | <450 % |

| Chemical Resistance | List Available | |

| * Values Relative to Foam Density | ||

This product assists in reduction of energy expenditures for homes and businesses. This soy-based foam is more environmentally responsible, and more efficient than current methods of insulation. The foam can also be used to build Insulated Concrete Forms and Structural Insulated Panels. This product (biopolymer) will be the one source industry leader in alternatives to petroleum based products, with a multitude of uses.

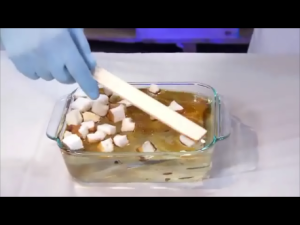

Soy-based Spray Foam Insulation is manufactured from renewable American grown soy beans. Among its best features are that it expands to 100 times its volume to completely fill every space and void, creating both a barrier and thermal seal. The thermal seal keeps your heating and cooling costs low. The barrier keeps pollutants out of your home and greatly reduces noise pollution. As an inert substance Soy-Based Spray Foam Insulation retains its structural integrity for the life of your home. It is not affected by moisture, mold, insects or rodents.

Paradigm Shift in Housing The need for sustainable house throughout the country and the world is tremendous. The rising cost of lumber and labor to build homes are to the point of being Out of reach.