Green Global Projects

Environmentally Friendly Products and Services

We have an ideal answer to the global problem of Waste Management, Waste Disposal and Power Generation System. There's absolutely no need to waste money trucking combustible waste anywhere or even 'chipping' it to be dumped in landfills. Our mobile system can get rid of it in a small fraction of the time, with virtually zero emissions of any kind.

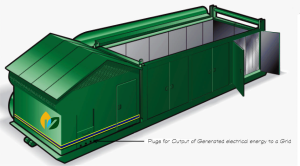

These units come in six sizes ranging from 19 ft. (5.8m) long to 37 ft. (11.4m), each made from heavy steel casing lined with very strong thermal-ceramic refractory "panels".

Ease of Operation With NO Site Preparation Needed!

The incredible thing about this unit is that once it is delivered to a landfill site it can be operational within an hour. All units are mobile.

All one needs is a relatively flat and clear space near the landfill. The unit is placed there with absolutely no other construction or site preparation necessary. With trained personnel we can the have unit working in a few hours.

Waste is loaded into the "firebox" and a small amount of accelerant (diesel oil) is used to ignite it. Once there is sufficient heat, the patented diesel-driven unit engages and forcefully blows across the top throughout the disposal process. The unit forces the smoke and particulates back into the combustion chamber over and over again literally burning them away.

100 tons of waste is reduced to two tons of sterile ash which might be used as fertilizer or simply deposited in the landfill. A remarkable 98% reduction in waste!

Six Models - One for Every Situation

All models work in the same way and can operate 24/7 or until the ash needs to be cleaned out. That too is a very simple procedure.

Once the ash is cooled sufficiently, the back doors of the unit are opened and the ashes easily removed by a front-end loader or similar device. The fact that there is no floor built into the unit makes this even easier.

The other option is to have a crane device simply lift the unit and place it down somewhere else, leaving the ash to be pushed into the landfill.

Our largest unit can turn 10 tons of combustible waste into sterile usable ash in one hour. Because of the special ceramic panels within the firebox, these units can reach 1000 C when at full operation. Obviously safety needs to be a constant concern in operating these units.

The Value of Mobility

We've stressed the mobility of all these units. This mobility translates into incredible economic value because the solution can be taken right to the problem, rather than having the huge expense of trucking the problem to the solution. One unit, therefore, can be kept constantly productive by moving it from landfill to landfill as needed.

A mobile unit can easily be pulled behind any standard pick-up truck! That means it can be efficiently taken from farm to farm or from community to community with minimal effort over roads that large trailers would find impassable. Again, it works exactly like the large models so care in operation has to be paramount.

The larger units require the appropriate flatbed trailer and the lifting equipment to get it on and off the trailer bed. Our experience is that in most situations the large units are left to do their work in one place usually for several months or even permanently if it's a large landfill.

The Power Generation Electricity Generator

We are able to attach our proprietary "Power Gen" electricity generator to these units in order to make good use of the heat which otherwise would be lost.

The Power Gen is built using the existing AC design with one modification. The thermal ceramic panels are replaced with those that contain a heat transfer apparatus inside them. That's how the heat gets to the actual power generator which is attached to the unit. It means that this option must be included at the time of the order or planned ahead.

In the industry this is known as "integrated distributed power waste to energy system" and it's a phenomenally valuable tool. Here are three example applications:

1. Especially in remote rural areas hospitals and schools can generate electricity while solving community waste problems at the same time.

2. The electricity generated can be used to recharge batteries to operate battery-dependent equipment. In some operations even large equipment like heavy loaders or other vehicles used in forestry can operate by battery power and have those batteries recharged by the Power Gen overnight. This reduces operating costs substantially.

3. Where there is access to the country or city's electricity grid, it is possible to sell electricity generated by the AC Power Gen back into the grid. In North America this has become a significant revenue center for some operations.

There are many variables that influence the cost of the Power Gen option, such as how much power you want to generate and which AC model you want to attach it to e.g. using the mid-range 200 series ACT unit. Between 100 and 125 kwh of power can be generated by this combination.

The Water Distiller

There is an unfortunate reality in the correlation between landfills and contaminated water tables. Where there is a lot of animal waste the problem worsens. That of course means contaminated drinking water. We don't need to delve into the health, social and economic hardships are created. Clean water is becoming the most valued resource around the planet.

You can now equip your unit with water distillation device. This can be used in:

1. Waste water treatment (animal and human) to prevent the spread of contamination.

2. Revitalizing recycled water for industry.

3. Desalinating water.

4. Generating potable water for drinking and personal hygiene.

5. Disaster areas where hurricanes and earthquakes have disrupted normal water supplies.

Depending on the size of the AC unit and what is being burned, we can produce approximately 1,000 gallons (3,785 liters) or more of pure water from one unit in full operation. The amount produced depends partly on the nature of the water being distilled. Obviously the contaminated water that is to be purified needs to be reachable from the unit location.

As with the Power Generator, pricing the Water Distillation device depends on a number of variables.

Supplemental Hood

We also offer a patented 'Supplemental Hood' device for the AC unit that employs a very sophisticated "coalescence filtration system" which enables the disposal of tires, other petroleum products and toxic waste all without harmful emissions.

While the primary purpose of this supplemental hood is to significantly reduce toxic emissions, it also increases the effectiveness of both the Power Generation and Distillation equipment rather significantly. The reason is that even more of the heat energy is captured and used.

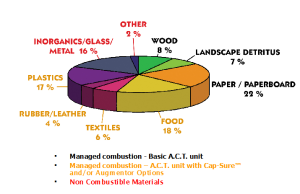

As noted, the most important function of "The Hood" is that it provides a unique filter to capture a broad variety of emissions including CO2, NOx, SOx and other particulates. This expands the AC unit's ability to dispose of waste streams beyond vegetative and agricultural waste to include municipal solid waste (MSW), tires, treated woods like railroad ties and construction waste. The EPA supports the addition of the Hood for such waste. We know the AC unit effectively burns these materials because the U.S. Military and NATO already use it to do so.

This hood filter is custom built as it needs to be fine-tuned to what toxic substances are actually being burned.

How the AC Technology is being used around the world

Please request for details at intprojects09@yahoo.com